Sublimation printing has become one of the most innovative methods in the printing industry, widely used for creating vibrant, long-lasting designs on various materials. From apparel and promotional products to signage and home décor, sublimation technology offers unmatched precision and durability. In this detailed guide, we will cover everything you need to know about sublimation printing, including its process, benefits, applications, required equipment, and expert tips to achieve the best results.

What Is Sublimation Printing?

Sublimation printing is a digital printing technique that uses heat and pressure to transfer dye directly into the surface of a material. Unlike traditional printing methods, where ink sits on top, sublimation turns the ink into a gas that permanently bonds with the fibers or coating of the substrate.

This method ensures that the design becomes a part of the material itself, producing prints that do not peel, crack, or fade easily. Custom sublimation printing works best on polyester fabrics and items coated with a polyester layer, making it ideal for apparel, mugs, tumblers, mousepads, and more.

How Does the Sublimation Printing Process Work?

The sublimation process consists of a series of carefully executed steps:

-

Design Creation – The artwork is created using specialized design software. Colors are prepared in CMYK mode for accuracy.

-

Printing the Transfer – The design is printed on sublimation transfer paper using sublimation inks.

-

Heat Press Transfer – The printed paper is placed onto the substrate and pressed with a heat press at high temperatures (usually 375°F–400°F).

-

Sublimation Reaction – The ink turns into a gas without becoming liquid, penetrating the polyester fibers or coating.

-

Finished Product – The result is a vivid, durable, and high-definition print that becomes a permanent part of the material.

Advantages of Sublimation Printing

The growing popularity of sublimation is due to its numerous advantages over other printing methods:

-

Vibrant and Full-Color Results – Sublimation produces rich, photo-quality images with smooth gradients.

-

Durability – Prints are resistant to peeling, fading, and cracking since the ink becomes part of the material.

-

Versatility – Works on a wide range of products, from clothing to ceramics and signage.

-

Cost-Effective for Small Runs – Ideal for customized, short-run production without setup fees.

-

Unlimited Design Potential – Allows for edge-to-edge, full-coverage printing with no limitations on color or detail.

Materials Suitable for Sublimation Printing

Not every material is suitable for sublimation. To achieve the best results, it is essential to use compatible substrates:

-

Polyester Fabrics – Best for t-shirts, sportswear, and uniforms.

-

Poly-Coated Hard Surfaces – Mugs, tumblers, keychains, and photo panels.

-

Home Décor Items – Pillow covers, blankets, wall art, and coasters.

-

Signage and Banners – Polyester-based materials for promotional displays.

Note: Sublimation does not work directly on cotton or dark fabrics unless a polyester coating or sublimation spray is applied.

Essential Equipment for Sublimation Printing

To set up a sublimation printing business, specific equipment and supplies are required:

-

Sublimation Printer – Specialized printers (e.g., Sawgrass, Epson EcoTank modified for sublimation).

-

Sublimation Ink – Dye-based ink formulated for heat transfer.

-

Sublimation Paper – Special paper designed to hold ink until heat is applied.

-

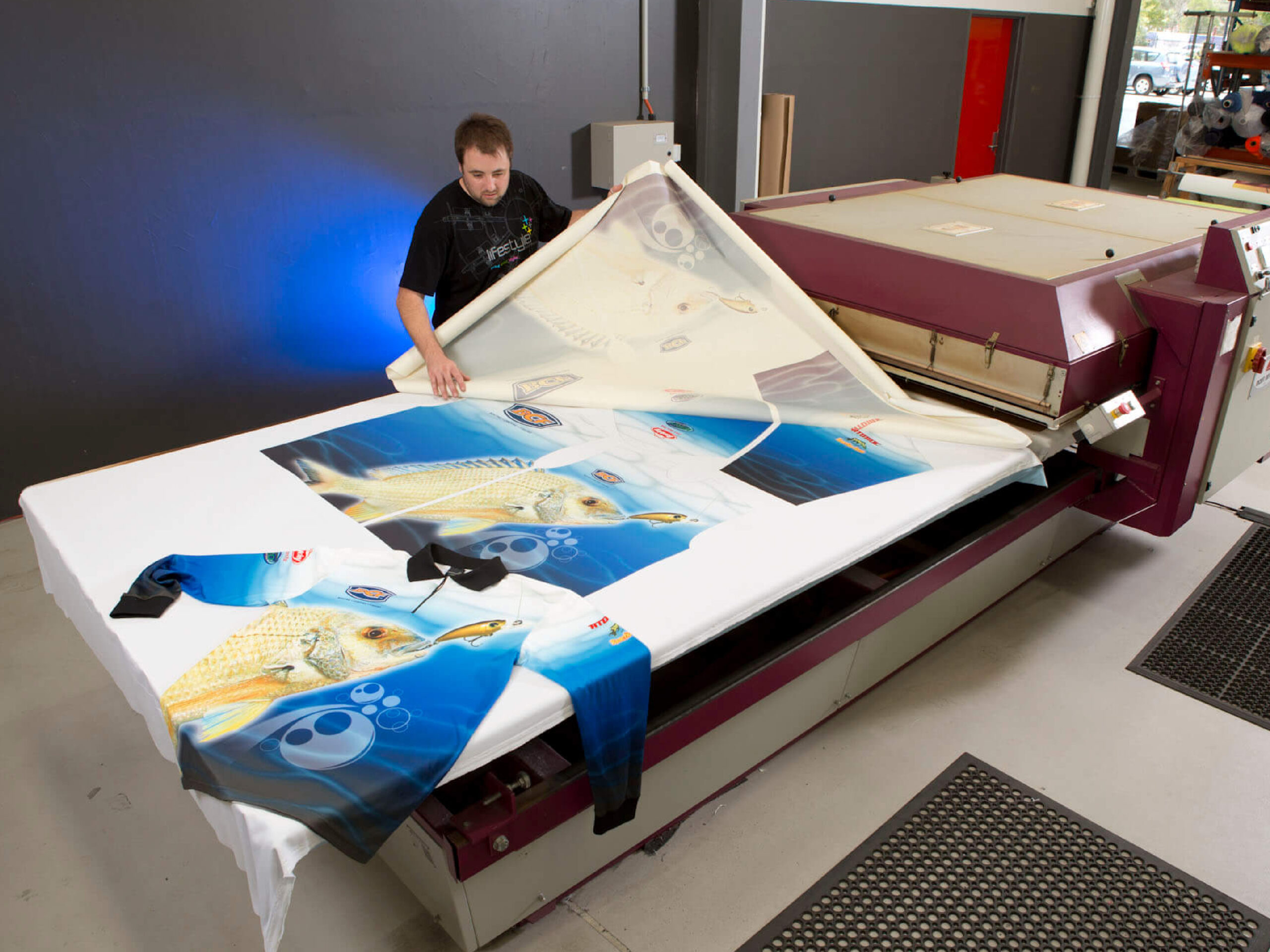

Heat Press Machine – Flat heat presses for fabrics, mug presses for cups, and 3D vacuum presses for complex items.

-

Protective Accessories – Heat-resistant tape, Teflon sheets, and silicone pads to prevent ghosting.

Step-by-Step Guide to Sublimation Printing

-

Choose Your Product – Select a sublimation-friendly blank item.

-

Design Preparation – Create or adjust your artwork, ensuring mirrored orientation.

-

Print on Transfer Paper – Use high-quality sublimation paper for optimal ink release.

-

Align and Secure – Position transfer paper on the product and secure with heat-resistant tape.

-

Press with Heat – Apply pressure at the recommended temperature and time.

-

Cool and Remove – Allow the item to cool before peeling the paper.

-

Quality Check – Inspect the finished product for clarity, color accuracy, and alignment.

Common Applications of Sublimation Printing

Sublimation is widely used across industries due to its adaptability:

-

Custom Apparel – Sports jerseys, team uniforms, fashion t-shirts, hoodies, and caps.

-

Promotional Products – Company mugs, mousepads, keychains, and giveaways.

-

Interior Design – Personalized cushions, curtains, and photo panels.

-

Corporate Branding – Branded merchandise, signage, and office décor.

-

Photography & Art – High-quality photo panels and wall prints.

Tips for Achieving Perfect Sublimation Prints

-

Use High-Resolution Images – Always work with 300 DPI for sharp results.

-

Control Heat and Pressure – Incorrect settings can cause fading or ghosting.

-

Test Before Bulk Production – Run samples to fine-tune time, temperature, and pressure.

-

Store Materials Properly – Keep sublimation paper and inks away from humidity.

-

Color Management – Use ICC color profiles for consistent, true-to-life prints.

Challenges in Sublimation Printing

While sublimation is a powerful method, it comes with certain limitations:

-

Only works on light-colored polyester or polyester-coated substrates.

-

Not suitable for 100% cotton fabrics.

-

Requires precise temperature and time control to avoid mistakes.

-

High upfront investment for equipment.

Despite these challenges, the long-term benefits and quality make sublimation a preferred choice for professional printing businesses.

Future of Sublimation Printing

With the rise of personalization trends, sublimation printing is expected to grow rapidly in industries such as fashion, home décor, and promotional merchandise. Advancements in eco-friendly inks, improved substrates, and large-format sublimation printers will continue to expand their possibilities.

As consumers demand more customized and sustainable solutions, sublimation printing will remain a top printing technology for businesses seeking to provide durable from Vel Clothing, high-quality products.

Conclusion

Sublimation printing is a revolutionary technique that offers unmatched vibrancy, durability, and versatility in product customization. By investing in the right equipment, mastering the process, and using high-quality materials, businesses can deliver professional-grade results that stand out in a competitive market.