In today’s industrial landscape, machinery operates under increasingly demanding conditions, requiring sophisticated lubrication solutions to maintain peak performance and longevity. Oil lubricant machines represent a critical component of modern manufacturing and industrial operations, yet many people remain unfamiliar with their fundamental principles and applications. For businesses exploring automated lubrication solutions, particularly those working with oil lubricant machine manufacturers in the UAE, understanding these systems is essential for making informed equipment decisions.

The evolution of lubrication technology has transformed how industries approach machinery maintenance and operational efficiency. What once required manual intervention and constant monitoring can now be automated through sophisticated oil lubricant machines that deliver precise amounts of lubricant exactly when and where needed. This technological advancement has revolutionised industrial operations across sectors ranging from automotive manufacturing to heavy construction equipment.

Understanding Oil Lubricant Machines

Oil lubricant machines, also known as automatic lubrication systems or centralised lubrication systems, are sophisticated mechanical devices designed to deliver controlled amounts of lubricating oil to machinery components at predetermined intervals. These systems eliminate the need for manual lubrication while ensuring consistent, accurate delivery of lubricants to critical mechanical parts.

At their core, these machines serve as the circulatory system for industrial equipment, much like how the human cardiovascular system delivers nutrients throughout the body. They maintain a steady flow of lubricating oil to bearings, gears, chains, and other moving components that require regular lubrication to function properly and avoid premature wear.

The fundamental principle behind oil lubricant machines revolves around creating a protective film between moving surfaces, reducing friction, dissipating heat, and preventing corrosion. By automating this process, these systems ensure that machinery receives optimal lubrication regardless of environmental conditions or operator availability.

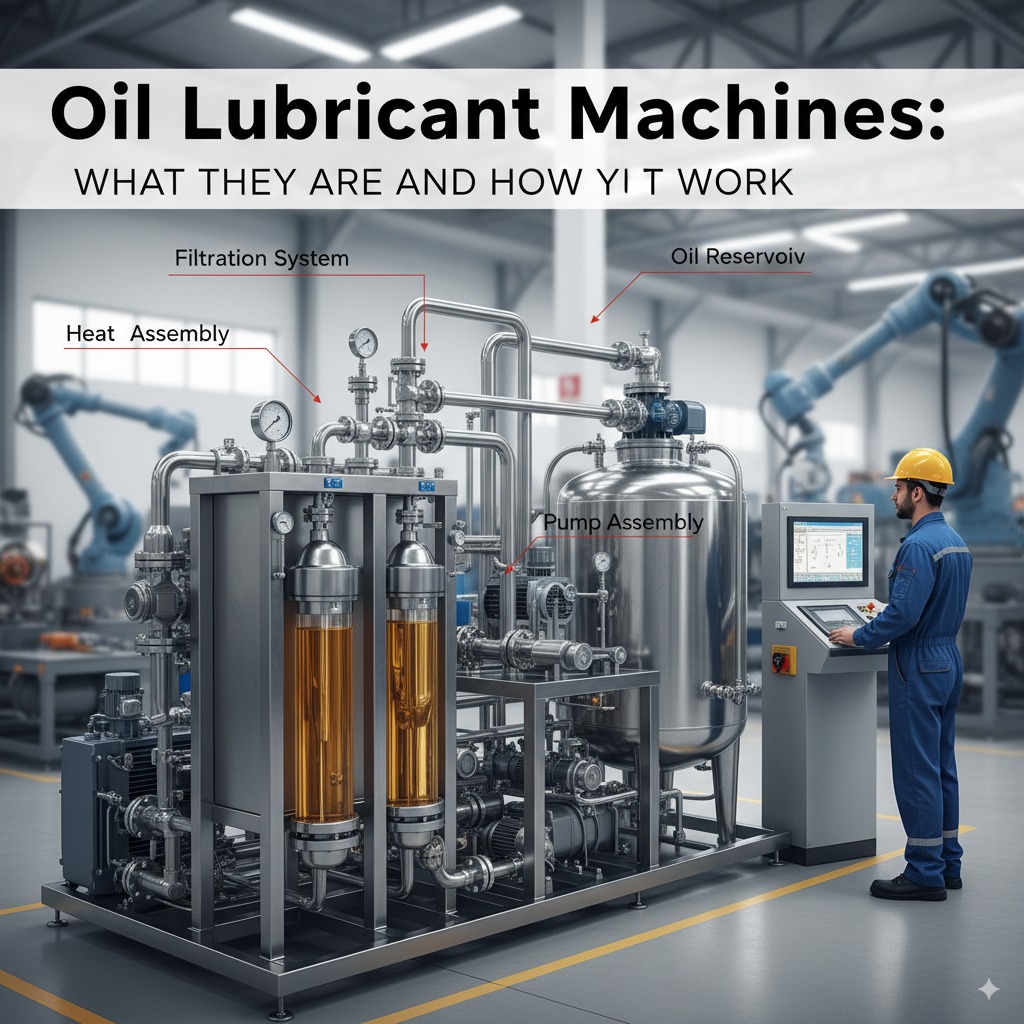

Core Components and Architecture

Modern oil lubricant machines consist of several interconnected components working in harmony to deliver precise lubrication. The central reservoir serves as the primary storage for lubricating oil, typically constructed from materials resistant to contamination and equipped with level monitoring systems to prevent dry running.

The pumping system forms the heart of the machine, utilising various technologies including gear pumps, piston pumps, or progressive cavity pumps, depending on the specific application requirements. These pumps generate the necessary pressure to distribute oil throughout the system while maintaining consistent flow rates regardless of system backpressure.

Distribution networks consist of primary and secondary lines that route lubricant from the central pump to individual lubrication points. These networks incorporate pressure regulators, flow dividers, and directional valves that ensure each lubrication point receives the correct amount of oil at the appropriate pressure.

Control systems manage the timing, duration, and frequency of lubrication cycles. Modern systems feature programmable logic controllers (PLCs) that can be customised for specific applications, allowing operators to adjust lubrication schedules based on operating conditions, load factors, and environmental variables.

How Oil Lubricant Machines Operate

The operational cycle of an oil lubricant machine begins with the control system initiating a lubrication sequence based on predetermined parameters such as time intervals, machine operating hours, or external triggers from connected equipment. When activated, the pump draws oil from the reservoir and pressurises the distribution system.

Oil flows through the primary distribution lines to secondary distributors or progressive dividers, which portion the lubricant into smaller, precise quantities for individual lubrication points. Each distribution point is calibrated to deliver the exact amount of oil required for optimal component lubrication without over-lubrication, which can lead to contamination and waste.

Throughout the process, monitoring systems track key parameters including system pressure, flow rates, oil levels, and pump performance. Advanced systems incorporate feedback mechanisms that can detect blockages, leaks, or component failures, automatically alerting operators to maintenance requirements or system malfunctions.

The cycle concludes when all designated lubrication points have received their programmed oil quantities. The system then enters a standby mode until the next scheduled lubrication cycle, continuously monitoring reservoir levels and system integrity to ensure readiness for the subsequent operation.

Types of Oil Lubricant Machines

Single-line systems represent the most straightforward configuration, utilising a single main line to distribute oil to multiple lubrication points. These systems are ideal for applications with relatively few lubrication points and similar oil requirements across all components.

Dual-line systems employ two alternating distribution lines, providing redundancy and enabling continuous lubrication of critical equipment. This configuration is particularly valuable for applications where lubrication interruption could result in significant equipment damage or production losses.

Progressive systems utilise mechanical dividers that sequentially distribute oil to each lubrication point in a predetermined order. This approach ensures that all points receive lubrication during each cycle and provides visual confirmation of system operation through indicator pins or other monitoring devices.

Multi-line systems feature individual lines to each lubrication point, offering maximum flexibility in terms of lubricant types, quantities, and timing. While more complex and expensive, these systems provide superior control for applications with diverse lubrication requirements.

Industrial Applications and Benefits

Oil lubricant machines find extensive application across diverse industrial sectors. In manufacturing facilities, they maintain production line equipment, including conveyor systems, packaging machinery, and assembly line components. The automotive industry relies heavily on these systems for stamping presses, welding equipment, and paint line machinery.

Construction and mining operations utilise oil lubricant machines for heavy equipment, including excavators, bulldozers, and processing equipment operating in harsh environmental conditions. The marine industry employs these systems for deck machinery, winches, and propulsion systems where manual lubrication would be impractical or dangerous.

The benefits of implementing oil lubricant machines extend beyond simple convenience. Reduced maintenance costs result from eliminated manual lubrication tasks and extended equipment life due to consistent, optimal lubrication. Improved safety outcomes occur by reducing worker exposure to hazardous lubrication tasks in dangerous locations.

Enhanced equipment reliability stems from consistent lubrication delivery regardless of operating conditions or personnel availability. Reduced lubricant consumption results from precise delivery systems that eliminate over-lubrication and waste associated with manual methods.

Selection Considerations for UAE Markets

When evaluating options for oil lubricant machines, several factors specific to UAE operating conditions require consideration. The region’s extreme temperatures and dusty environment demand systems with robust construction and superior sealing to prevent contamination and maintain performance reliability.

Local support infrastructure plays a crucial role in long-term system success. Establishing relationships with qualified suppliers who can provide ongoing technical support, spare parts availability, and maintenance services ensures optimal system performance throughout its operational life.

Environmental compliance considerations are increasingly important, particularly regarding lubricant disposal and system efficiency. Modern systems should incorporate features that minimise environmental impact while meeting local regulatory requirements.

Maintenance and Operational Best Practices

Successful operation of oil lubricant machines requires adherence to established maintenance protocols and operational best practices. Regular system inspections should include checking reservoir levels, monitoring pressure readings, and verifying proper operation of all distribution points.

Preventive maintenance schedules should encompass filter changes, pump inspections, and distribution system cleaning to maintain optimal performance and prevent costly failures. Documentation of maintenance activities and system performance provides valuable data for optimising lubrication schedules and identifying potential issues before they impact operations.

Operator training ensures proper system operation and early identification of potential problems. Well-trained personnel can maximise system benefits while minimising the risk of costly equipment damage due to improper operation or maintenance oversight.

Future Trends and Technology Integration

The future of oil lubricant machines increasingly incorporates digital technologies and IoT connectivity. Smart systems provide real-time monitoring, predictive maintenance capabilities, and remote diagnostic features that enhance operational efficiency and reduce maintenance costs.

Integration with enterprise maintenance management systems enables automated work order generation, inventory management, and performance tracking that streamlines maintenance operations and improves equipment reliability.

Conclusion

Oil lubricant machines represent essential infrastructure for modern industrial operations, providing automated, precise lubrication that enhances equipment reliability while reducing maintenance costs and improving safety outcomes. Understanding their operation, benefits, and selection criteria enables informed decisions that support long-term operational success. As industrial operations continue evolving toward greater automation and efficiency, these systems will play an increasingly vital role in maintaining competitive advantage and operational excellence.

Thanks, homesarah.com