The biggest enemy of metals in harsh environments is corrosion. From marine seawater systems to chemical processing units, corrosion slowly eats away at performance, reliability, and safety. That’s why engineers pay close attention when selecting alloys for components that will face chloride-rich environments, acids, or fluctuating conditions. Monel 400 Round Bars stand out as one of the most reliable solutions because they combine toughness, versatility, and — most importantly — outstanding resistance to corrosion.

In this article, we’ll break down what makes Monel 400 such a trusted material, how it resists different forms of corrosion, and where its benefits are most evident in real-world applications.

Understanding corrosion and why it matters

Corrosion is the gradual destruction of metal caused by chemical or electrochemical reactions with its environment. While it may seem like just surface rust or minor pitting, corrosion in industrial systems often leads to:

-

Equipment downtime

-

Expensive repairs or replacements

-

Safety hazards due to leaks or structural failure

-

Lower efficiency in heat transfer and fluid handling systems

In industries like marine, oil and gas, and chemical processing, these issues are not minor inconveniences; they can mean millions in lost revenue and serious risks to safety. That’s why Monel 400 Bars, known for their corrosion resistance, are often specified for mission-critical parts.

What gives Monel 400 its corrosion resistance?

Monel 400 is a nickel-copper alloy, typically containing around 63% nickel and 28–34% copper, with small amounts of iron, manganese, and silicon. This specific chemical composition is what delivers its unique balance of corrosion resistance.

Here’s how the alloy works in practice:

-

Nickel content provides immunity to chloride-induced stress corrosion cracking — a common failure mode for many stainless steels.

-

Copper content strengthens resistance to hydrochloric acid, hydrofluoric acid, and seawater environments.

-

Solid solution strengthening makes the alloy tough and durable, resisting not just chemical attack but also erosion from high-velocity fluids.

In simple terms, Monel 400 isn’t just “rust-resistant” — it’s engineered to withstand some of the most corrosive conditions that industrial equipment ever faces.

Types of corrosion Monel 400 resists

1. General corrosion

Many alloys corrode evenly across their surface when exposed to chemicals or seawater. Monel 400 resists uniform corrosion better than common stainless steels in environments such as hydrofluoric acid, alkalis, and seawater. This ensures the material maintains thickness and strength over longer service lives.

2. Pitting corrosion

In chloride-rich conditions, stainless steels often suffer localized attack in the form of pits. Monel 400’s nickel-copper chemistry makes it far less vulnerable to pitting, especially in seawater systems and brines. What this really means is fewer hidden weak spots that can cause sudden leaks or failures.

3. Stress corrosion cracking (SCC)

SCC occurs when tensile stress and corrosive environments act together, leading to sudden and catastrophic cracking. One of Monel 400’s strongest advantages is its immunity to chloride-induced stress corrosion cracking. For marine shafts, pump housings, or chemical plant agitators, this is a game changer.

4. Galvanic corrosion

When different metals are coupled together in an electrolyte (like seawater), one corrodes preferentially. Monel 400, because of its stable nickel-copper mix, offers strong resistance when paired carefully with other metals. That’s why it’s used in fasteners, fittings, and joints in mixed-metal assemblies.

5. Erosion-corrosion

High-velocity seawater and slurry streams can strip protective films from surfaces, causing accelerated wear. Monel 400 holds its ground here too, resisting erosion-corrosion better than many stainless steels or brasses. It’s particularly useful in pump shafts and heat exchanger tubing that see high flow rates.

Real-world benefits in marine environments

The marine sector is unforgiving. Saltwater is one of the most aggressive natural environments for metals. Monel 400 Round Bars are widely used in propeller shafts, pump internals, fasteners, and condenser tubes precisely because they resist saltwater’s corrosive attack.

Ships that switch to Monel for critical parts often see fewer unscheduled dry-docks and less downtime caused by pitting failures or fastener corrosion. That predictability is a major financial advantage in shipping, where operational hours directly translate to revenue.

Advantages in chemical processing plants

Chemical plants are another world where corrosion can quickly ruin equipment. Hydrofluoric acid, caustic soda, and brines eat away at steels and copper alloys in no time. Monel 400 stands apart because it can handle these aggressive chemicals without significant degradation.

Common applications include:

-

Reactor vessels

-

Heat exchanger tubes

-

Pump and valve internals

-

Agitator shafts

-

Fasteners in corrosive atmospheres

Here, the corrosion resistance of Monel 400 Round Bars ensures both safety and process reliability — two things no plant can compromise.

Offshore and oil & gas applications

Offshore rigs and subsea systems combine seawater exposure with high pressures and sometimes sour gases. Failures in these settings are costly and dangerous. Monel 400 is often used for subsea fittings, riser components, and fasteners where corrosion resistance under stress is critical. Its ability to resist chloride SCC and erosion-corrosion makes it a safer, longer-lasting choice for offshore operators.

Comparing Monel 400 to stainless steel

It’s natural to ask: why not use stainless steels, which are often cheaper?

-

Chloride resistance: Stainless steels, especially 304 and 316 grades, are vulnerable to pitting and stress corrosion cracking in chloride-rich environments. Monel 400 resists both.

-

Acid resistance: While stainless steels handle many oxidizing acids, Monel outperforms them in non-oxidizing acids such as hydrofluoric and hydrochloric acid.

-

Longevity: Stainless steels may work in less aggressive environments, but for continuous seawater or caustic service, Monel 400 delivers a longer, safer lifespan.

So, while stainless steels are sufficient for general service, Monel 400 is the smarter investment where failure risks are high.

Fabrication without losing corrosion resistance

One underrated benefit of Monel 400 is that it maintains its corrosion resistance even after machining, welding, or forming. Many alloys lose protective films or require careful heat treatments to restore corrosion protection. Monel 400 doesn’t — it remains reliable as long as proper procedures are followed.

This makes it attractive for manufacturers of complex components like pump shafts, welded heat exchanger shells, or custom fittings for marine and chemical plants.

Lifecycle cost advantages

The initial cost of Monel 400 Bars is higher than carbon steels or even some stainless steels. But the real calculation is lifecycle cost. Consider:

-

Lower downtime from corrosion failures

-

Fewer replacements and repairs

-

Longer service intervals

-

Improved safety and reliability

When all of this is factored in, Monel 400 often proves the more economical choice for mission-critical parts. In short: paying more upfront often saves significantly more down the road.

Practical guidelines for using Monel 400

-

Use it in environments where chlorides, acids, or seawater are a constant factor.

-

Specify cold-worked bars for added strength if needed, since the alloy isn’t heat-treatable.

-

Apply proper welding techniques with recommended filler metals for lasting joints.

-

Pay attention to galvanic isolation when pairing with dissimilar metals.

-

Design components to avoid stagnant crevices and allow for inspection.

You can also read – https://www.homesarah.com/how-to-shop-like-a-pro-at-vintage-clothing-stores-a-detailed-guide/

Conclusion

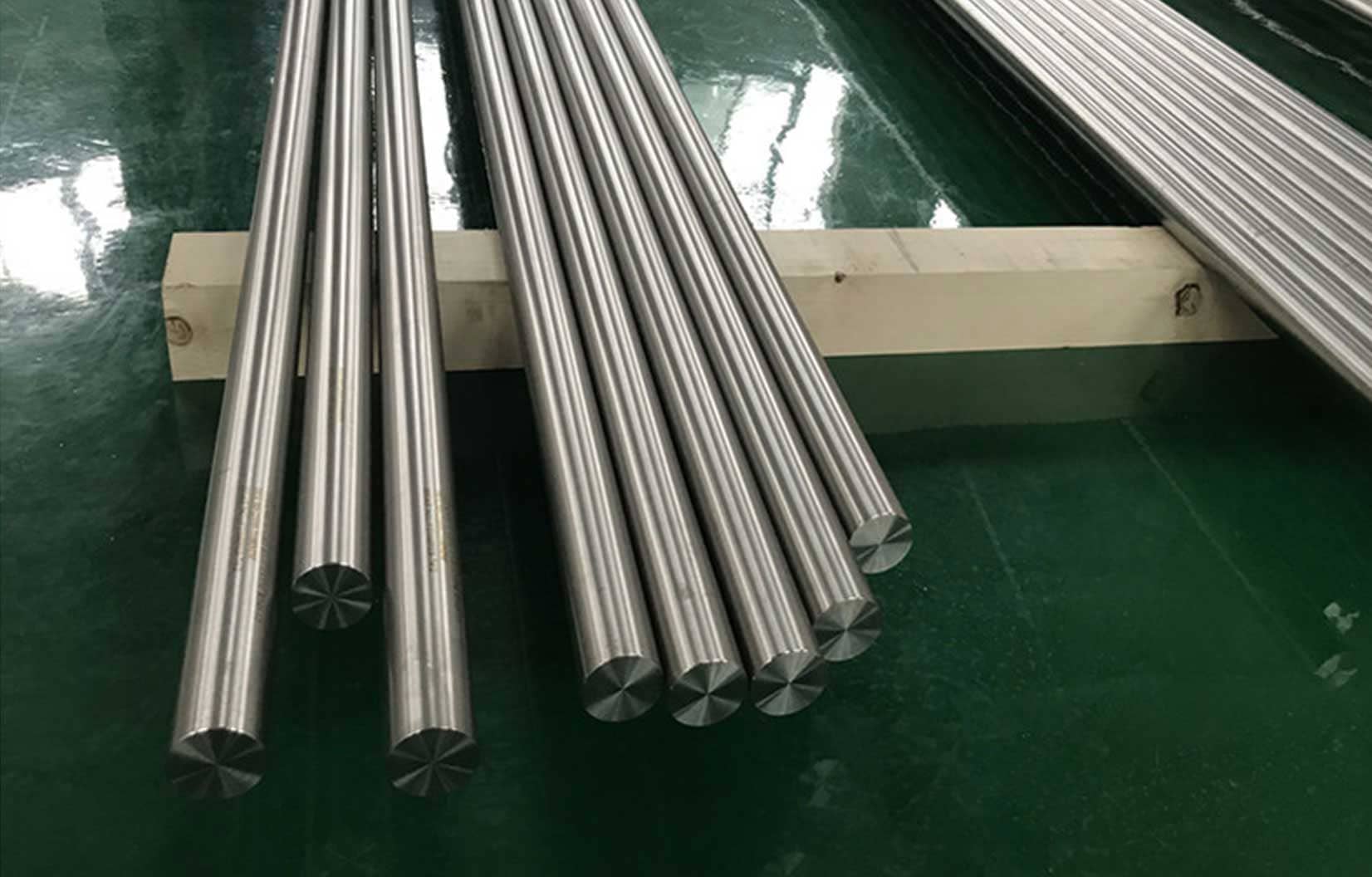

Corrosion resistance isn’t just a technical advantage — it’s the foundation of reliability in marine, chemical, and offshore systems. Monel 400 Round Bars bring proven performance against uniform corrosion, pitting, stress corrosion cracking, erosion, and galvanic attack. That’s why engineers continue to specify them for shafts, valves, fasteners, and heat exchangers in the harshest service conditions.

Yes, they cost more upfront than stainless steels, but the benefits — longer lifespan, fewer failures, and predictable performance — outweigh the difference many times over.

By choosing certified Monel 400 Bars from Nextgen Steel and Alloys, you get more than just material — you get assurance. With traceability, test certificates, and dependable supply, Nextgen Steel and Alloys helps shipyards, chemical plants, and offshore operators source the right alloy for critical service.