IMARC Group has recently released a new research study titled “Mexico 3D Printing Market Size, Share, Trends and Forecast by Technology, Process, Material, Offering, Application, End-User, and Region, 2025-2033,” which offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends, and competitive landscape to understand the current and future market scenarios.

Mexico 3D Printing Market Overview

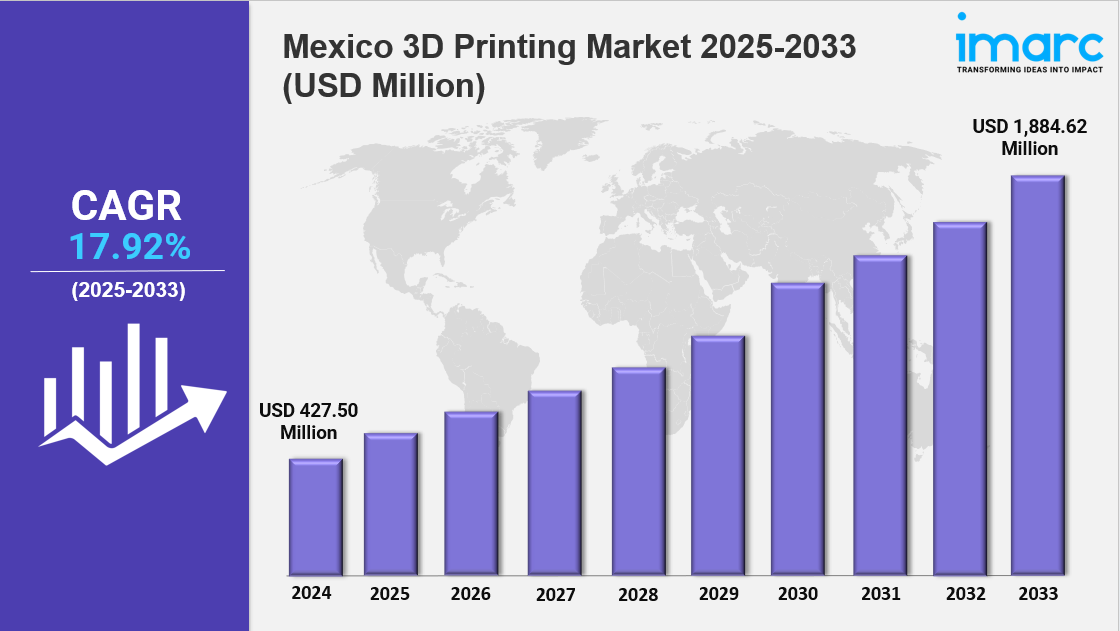

The Mexico 3D printing market size reached USD 427.50 Million in 2024. Looking forward, IMARC Group expects the market to reach USD 1,884.62 Million by 2033, exhibiting a growth rate (CAGR) of 17.92% during 2025-2033.

Market Size and Growth

Base Year: 2024

Forecast Years: 2025-2033

Historical Years: 2019-2024

Market Size in 2024: USD 427.50 Million

Market Forecast in 2033: USD 1,884.62 Million

Market Growth Rate 2025-2033: 17.92%

Request for a sample copy of the report: https://www.imarcgroup.com/mexico-3d-printing-market/requestsample

Key Market Highlights:

Growing adoption across automotive, aerospace, and healthcare industries driving market expansion

Increasing use of advanced materials and rapid prototyping boosting manufacturing efficiency

Government initiatives and rising investments in Industry 4.0 accelerating 3D printing innovation

Mexico 3D Printing Market Trends

The Mexico 3D printing market is expanding quickly as nearshoring continues to reshape manufacturing across North America. Companies moving production closer to the United States are turning to 3D printing to cut costs, reduce material waste, and speed up production timelines. In aerospace hubs like Querétaro and Chihuahua, major players such as Bombardier and Safran use metal additive manufacturing to produce lightweight engine and structural parts—reducing material waste by nearly 50% and lowering production costs by up to 30%. This shift reflects the growing Mexico 3D printing market demand among industrial manufacturers seeking efficiency and flexibility.

Automotive Sector Embraces Additive Manufacturing

The automotive industry in Nuevo León is another strong growth driver. Manufacturers are now integrating 3D printing directly into their production lines to create custom tools and components on-site, reducing downtime and improving design agility. Around 68% of factories in this sector already use connected 3D printing systems for real-time performance tracking. However, the industry still depends heavily on imports—about 85% of high-grade printers come from the U.S. and Germany, and most advanced metal powders are sourced internationally.

Healthcare Innovation Strengthens Market Growth

Healthcare is becoming one of the most dynamic areas in the Mexico 3D printing market. Institutions such as the Instituto Nacional de Rehabilitación in Mexico City are producing customized titanium spinal implants that enhance recovery outcomes for patients. Dental labs in Monterrey and Guadalajara are also using 3D printing to create thousands of aligners each month, making Mexico a regional leader in dental applications. Support from COFEPRIS has helped accelerate adoption, although limited technical training and material access in rural regions still pose challenges.

Sustainability and Technological Progress

Sustainability is becoming a central focus in shaping the future of Mexico’s 3D printing market, influencing both innovation and industrial practices across the country. As environmental awareness grows globally, Mexican companies, startups, and research institutions are increasingly adopting sustainable approaches to manufacturing. This transformation is not only motivated by ecological responsibility but also by the economic opportunities that come from reducing material waste, energy consumption, and production costs.

One of the most promising examples of this trend is Reciclados 3D, a pioneering Mexican startup that has gained attention for its creative use of recycled materials. The company collects discarded plastics, used automotive parts, and other industrial waste and repurposes them into high-quality 3D printing filaments. This approach helps reduce the environmental impact of plastic waste while offering an affordable source of raw materials for small and medium-sized manufacturers. By closing the loop between waste and production, Reciclados 3D exemplifies how circular economy principles can be applied in additive manufacturing.

Large corporations are also exploring sustainable applications of 3D printing. The construction giant CEMEX has been experimenting with 3D-printed concrete that can significantly reduce carbon emissions—by as much as 50% compared to traditional methods. Through these innovations, CEMEX aims to develop a more sustainable construction process that minimizes the use of cement, one of the most carbon-intensive materials in the world. This initiative has the potential to reshape how infrastructure is built in Mexico, particularly in affordable housing projects where cost efficiency and environmental performance are critical.

Universities and government institutions play a key role in supporting this transition toward greener 3D printing. Several academic research centers, often in collaboration with public agencies, are studying alternative bio-based materials such as algae-derived plastics, corn starch composites, and recycled resin blends. These materials can help replace petroleum-based plastics that dominate the market today. To encourage private investment in these sustainable technologies, the Mexican government has introduced incentives like research grants, startup incubators, and tax benefits for companies that develop or adopt eco-friendly materials.

Despite these positive developments, several challenges continue to hinder the widespread adoption of sustainable 3D printing in Mexico. The country’s recycling infrastructure remains underdeveloped in many regions, limiting the availability of high-quality recycled feedstock. Additionally, electricity consumption in 3D printing processes is relatively high, especially when compared to traditional manufacturing techniques. Since a large portion of Mexico’s energy still comes from fossil fuels, the environmental benefits of 3D printing can be partially offset by its carbon footprint.

To achieve large-scale sustainability in this industry, further investment in renewable energy, material recovery systems, and education will be crucial. As the Mexican 3D printing ecosystem matures, collaborations among startups, universities, and corporations could accelerate the shift toward greener technologies. Overall, while the path is complex, Mexico’s commitment to sustainability in 3D printing demonstrates a growing awareness that innovation and environmental stewardship must go hand in hand to create a truly sustainable future.

Market Performance and Key Indicators

As of 2024, the Mexico 3D printing market is valued at roughly USD 215 million, with the aerospace and automotive sectors contributing more than 50% of total output. Continued global supply chain disruptions have encouraged local industries to adopt additive manufacturing as a reliable alternative. Healthcare demand is rising as medical tourism and new production regulations boost local manufacturing capacity. Sustainable materials, including recycled and plant-based inputs, now represent nearly 20% of total usage—highlighting a growing shift toward green production.

Mexico 3D Printing Market Outlook

Looking ahead, the Mexico 3D printing market outlook remains optimistic. To sustain long-term growth, the country must close the skills gap—currently estimated at 8,000 trained technicians—and strengthen local supply chains for raw materials. The next phase of innovation will come from integrating hybrid systems that combine CNC machining with 3D printing, along with advancements in design and simulation software.

According to the latest Mexico 3D printing market forecast, the industry is expected to reach around USD 720 million by 2033. With continued investment, sustainable practices, and a strong focus on innovation, Mexico is well-positioned to become a leading additive manufacturing hub in Latin America.

Mexico 3D Printing Market Segmentation:

The market report segments the market based on product type, distribution channel, and region:

Technology:

- Stereolithography

- Fused Deposition Modeling

- Selective Laser Sintering

- Electron Beam Melting

- Digital Light Processing

- Others

Process:

- Binder Jetting

- Directed Energy Deposition

- Material Extrusion

- Material Jetting

- Powder Bed Fusion

- Sheet Lamination

- Vat Photopolymerization

Material:

- Photopolymers

- Plastics

- Metals and Ceramics

- Others

Offering:

- Printer

- Material

- Software

- Service

Application:

- Prototyping

- Tooling

- Functional Part Manufacturing

End-User:

- Consumer Products

- Machinery

- Healthcare

- Aerospace

- Automobile

- Others

Region:

- Northern Mexico

- Central Mexico

- Southern Mexico

- Others

Competitive Landscape:

The market research report offers an in-depth analysis of the competitive landscape, covering market structure, key player positioning, top winning strategies, a competitive dashboard, and a company evaluation quadrant. Additionally, detailed profiles of all major companies are included.

Key Highlights of the Report

- Market Performance (2019-2024)

- Market Outlook (2025-2033)

- COVID-19 Impact on the Market

- Porter’s Five Forces Analysis

- Strategic Recommendations

- Historical, Current and Future Market Trends

- Market Drivers and Success Factors

- SWOT Analysis

- Structure of the Market

- Value Chain Analysis

- Comprehensive Mapping of the Competitive Landscape

About Us:

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC’s information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company’s expertise.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91-120-433-0800

United States: +1 201971-6302