Every industry today depends on reliable electrical systems. From cars and planes to medical equipment and industrial machinery, smooth performance starts with strong wiring connections. That’s where cable harnesses step in. A cable harness brings together multiple wires into one organised assembly, keeping systems safe, efficient, and long-lasting. When designed and produced with precision, these harnesses don’t just carry signals and power—they protect entire operations from breakdowns and faults.

The Role of Cable Harness Manufacturing

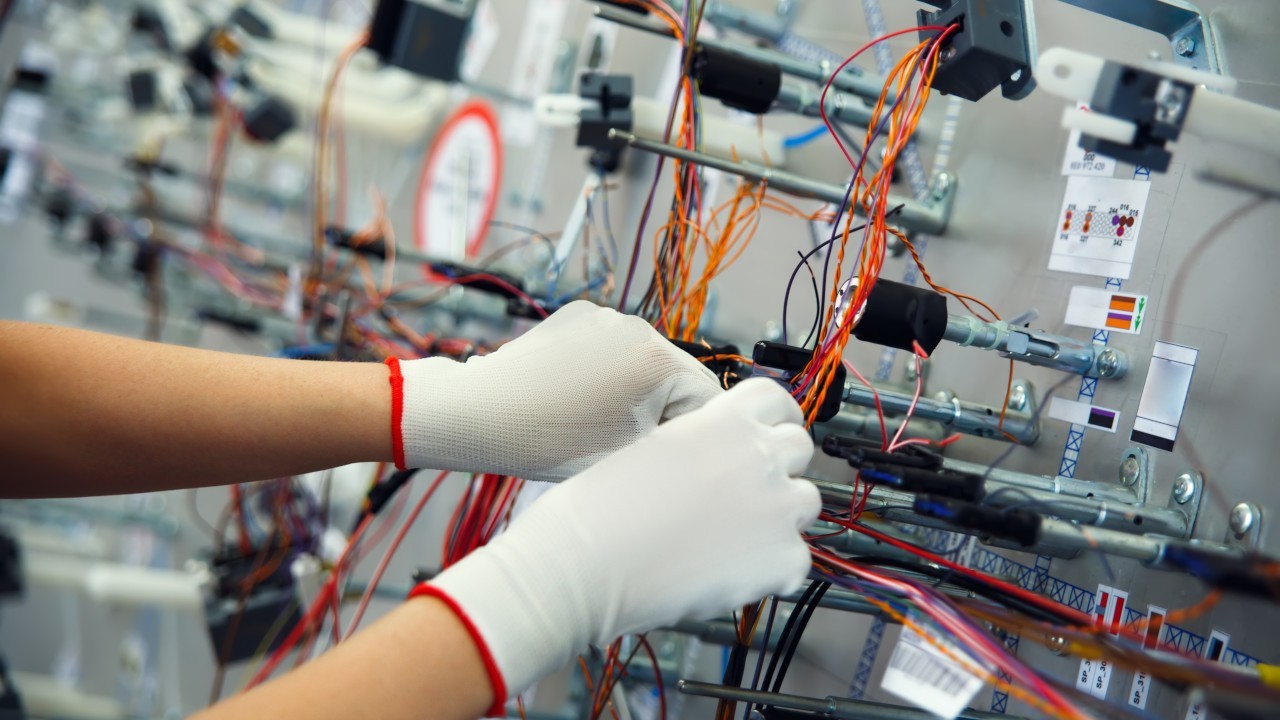

Cable Harness Manufacturing is the process of designing, assembling, and testing grouped wires to form a single harness. Instead of having loose wires running everywhere, a harness brings them together in one structured unit. This approach keeps electrical systems tidy, reduces installation time, and improves safety. More importantly, it ensures connections work seamlessly in demanding environments such as factories, aircraft, or heavy-duty vehicles. A properly manufactured harness turns complexity into simplicity, giving businesses peace of mind that operations will keep running smoothly.

Why Quality Matters in Cable Harnesses

Durability in wiring is not a luxury—it’s essential. A weak harness can lead to costly failures, downtime, and even safety risks. High-quality harnesses are built to withstand vibration, heat, moisture, and constant use. Each connection is tested, each cable is measured, and each material is chosen with performance in mind. By focusing on quality during the build process, manufacturers deliver harnesses that last longer and perform better, no matter the application.

Precision Engineering for Every Project

Accuracy is the backbone of every harness. From initial design to final testing, precision is key. Advanced tools and automated systems allow each component to be cut, crimped, and assembled with exact detail. This level of engineering eliminates errors and ensures the finished harness matches the exact requirements of the customer. No shortcuts are taken, which means every wire fits perfectly, every connection is solid, and every project is delivered to the highest standard.

Custom Solutions for Different Industries

Every sector has unique needs, and one-size-fits-all wiring doesn’t work. Aerospace demands lightweight, high-performance solutions. Automotive requires rugged, durable harnesses that can handle constant movement. Industrial machinery needs strong assemblies that can perform under heavy loads. Medical equipment demands absolute precision where safety is critical. By tailoring harnesses to each industry, manufacturers create products that not only work but thrive in the environments they serve.

Streamlined Production for Consistency

Time is money in every industry, and delays can cause serious setbacks. A streamlined production process ensures fast turnaround without sacrificing quality. Automation speeds up repetitive tasks, while skilled engineers oversee the process to maintain accuracy. The result is consistent, repeatable harnesses—whether for small projects or large-scale production. This balance of speed and precision allows businesses to receive reliable harnesses exactly when needed.

Testing for Safety and Reliability

A harness isn’t complete until it has passed through strict testing. Each connection must hold firm, each cable must carry the right signal, and the entire assembly must perform under pressure. Testing identifies any potential weaknesses before a harness leaves the production line. By focusing on reliability during testing, manufacturers guarantee that clients receive harnesses ready to perform in real-world conditions without fault.

The Benefits of Professional Harness Manufacturing

The advantages of using a professional harness manufacturer extend far beyond the product itself. Time is saved during installation, as pre-assembled harnesses reduce the need for on-site wiring. Errors are reduced, since everything is built and tested in controlled conditions. Costs are lowered in the long term, as durable harnesses require fewer replacements. Safety improves, as organised wiring reduces the risk of accidents or electrical issues. In short, businesses gain peace of mind knowing that wiring will support their systems without unexpected problems.

Cable Harnesses and Efficiency

Efficiency is a major factor in modern production. Harnesses not only save time during installation but also simplify maintenance. Instead of dealing with dozens of loose wires, technicians can quickly identify and address issues within a structured harness. This level of organisation improves overall workflow and reduces downtime. By choosing high-quality harnesses, businesses align efficiency with reliability, creating smoother operations across the board.

Durability That Stands the Test of Time

Durability is about more than just strong materials. It’s about design, precision, and testing combined. A well-made harness resists wear, handles environmental stress, and continues to perform year after year. In industries where failure is not an option, durability provides confidence. From rough terrain vehicles to sensitive medical machines, a durable harness keeps systems running safely and smoothly, no matter how demanding the conditions.

Why Choose LCA Group for Cable Harness Manufacturing

LCA Group has established itself as a leader in providing reliable wiring solutions. The company’s focus on streamlined processes, automation, and skilled craftsmanship ensures every harness meets the highest standards of quality and consistency. By supporting projects of all sizes, from one-off builds to large production runs, LCA Group delivers services that adapt to client needs. From control panels to complex looms, the team ensures every assembly is accurate, durable, and ready for integration.

Supporting Complex Projects with Expertise

Some projects require more than simple wiring solutions. Complex control systems, advanced machinery, and intricate installations demand a higher level of expertise. LCA Group provides that support by managing the preparation process, allowing clients to focus on installation and integration. This approach reduces the risk of delays, errors, or failures, making even the most complex projects more manageable.

The Future of Cable Harness Manufacturing

The future is all about smarter, faster, and more efficient solutions. With automation advancing and industries demanding more precision, harness manufacturing continues to evolve. Materials are becoming stronger, designs more flexible, and production more sustainable. The demand for durable and efficient harnesses will only increase as technology grows, making quality manufacturing more important than ever.

Conclusion

Cable harnesses are the unsung heroes of modern industry. They provide order, safety, and durability in systems that power everyday life. Without them, cars wouldn’t run, planes wouldn’t fly, and factories wouldn’t operate. By focusing on quality, durability, and precision, manufacturers deliver harnesses that keep businesses moving forward. With proven expertise and a commitment to excellence, LCA Group continues to set the standard in Cable Harness Manufacturing, offering solutions that save time, reduce risk, and provide lasting value.