In today’s fast-paced manufacturing environment, precision and efficiency are crucial. CNC Turning Services play a vital role in producing high-quality components with tight tolerances and consistent finishes. Industries ranging from automotive to aerospace depend on these services to create reliable parts that meet strict specifications. By combining computer control with advanced machinery, businesses can achieve superior results while reducing production times.

What Are CNC Turning Services?

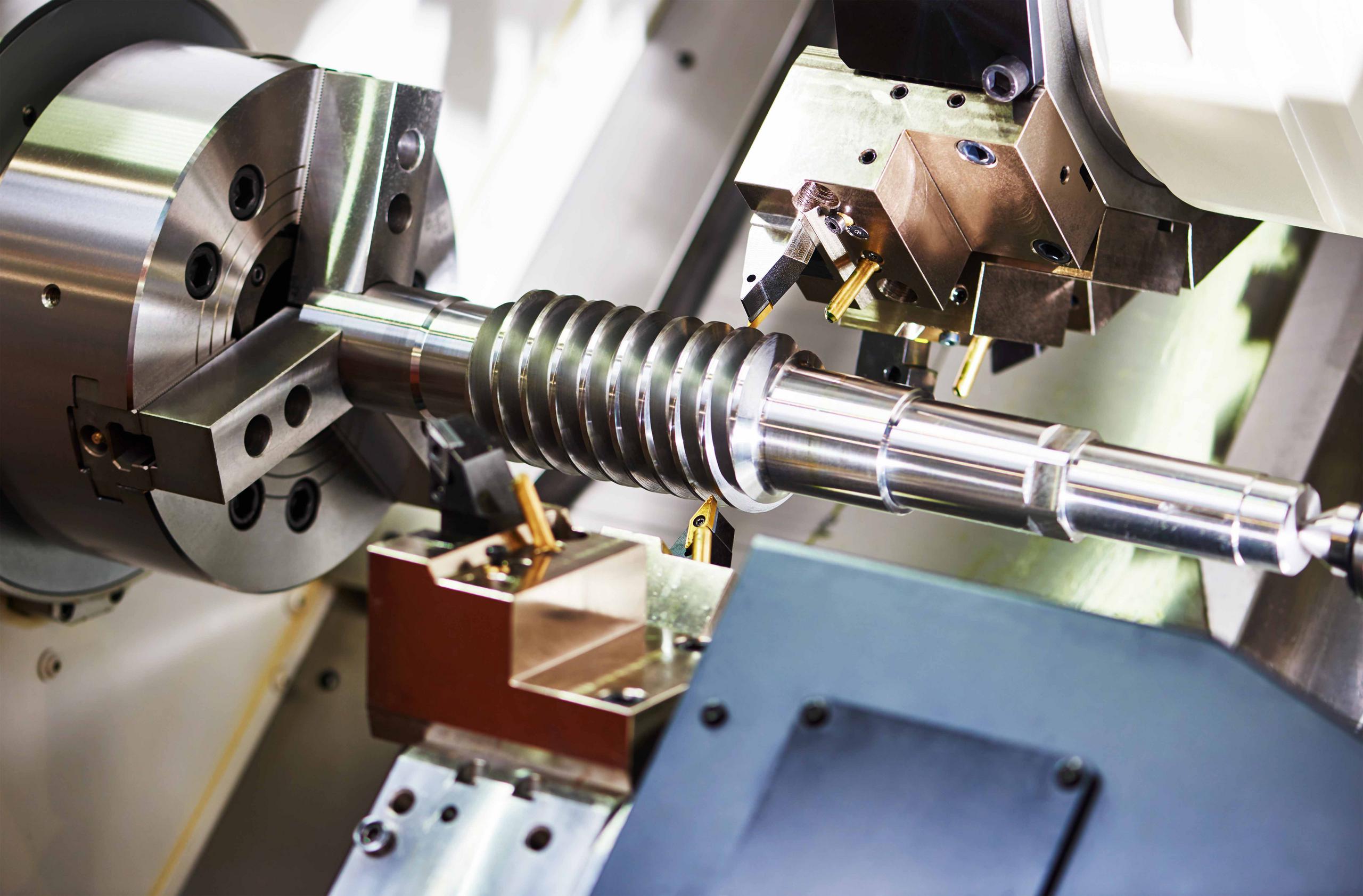

CNC Turning Services involve using computer numerical control (CNC) machines to shape raw materials into precise cylindrical parts. These services rely on high-speed cutting tools that rotate the material while removing excess stock. Unlike traditional manual turning, CNC technology enhances accuracy, consistency, and productivity, making it ideal for both low-volume prototyping and large-scale production.

The Role of CNC Lathe Machining

At the heart of many CNC Turning Services is CNC lathe machining, a process where computer-controlled lathes rotate the workpiece while specialized tools cut it into the desired shape. This method allows for the creation of parts with smooth surfaces and intricate geometries. From shafts to bushings, CNC lathes ensure precise results that manual methods often struggle to achieve.

Benefits of CNC Turning Services

Investing in CNC Turning Services provides manufacturers with numerous benefits that directly impact efficiency and quality.

Superior Precision and Accuracy

One of the main advantages is the ability to produce precision turned components with remarkable accuracy. The automated nature of CNC systems reduces human error and ensures every part matches exact specifications. This level of precision is critical for industries where safety and reliability cannot be compromised.

Efficiency in Cylindrical Part Manufacturing

Cylindrical shapes are common in industrial applications, and cylindrical part manufacturing through CNC turning ensures these parts are made quickly and consistently. Whether for automotive engines, medical devices, or aerospace structures, the process allows for scalable production without sacrificing quality.

Flexibility with Custom Turning Solutions

Another advantage of CNC Turning Services is their ability to handle custom turning solutions. Clients often require unique designs, specialized dimensions, or prototypes tailored to their specific projects. With CNC technology, it is possible to program and reprogram machines quickly, offering versatility to meet diverse needs without significant delays.

Cost-Effective Metal Turning Services

For many industries, metal turning services provide an affordable path to high-quality parts. Since CNC systems minimize material waste and reduce production errors, companies save costs while still achieving premium results. This cost-effectiveness makes CNC turning attractive for both small and large-scale operations.

Applications of CNC Turning Services

CNC Turning Services are widely used across multiple industries thanks to their reliability and adaptability.

Automotive Industry

In the automotive sector, precision turned components such as engine shafts, gears, and bolts are critical for vehicle performance and safety. CNC turning ensures these parts are durable, uniform, and capable of withstanding extreme conditions.

Aerospace and Defense

When it comes to aerospace, cylindrical part manufacturing is indispensable for producing high-performance components like turbine shafts and landing gear parts. The accuracy of CNC turning helps meet the stringent quality standards demanded by this industry.

Medical Field

Medical devices often require custom turning solutions to create surgical instruments and implants with high precision. CNC turning enables the production of these parts with smooth finishes and exact measurements, ensuring patient safety.

General Manufacturing

Beyond specialized sectors, metal turning services are essential in general manufacturing. From producing fasteners to rollers, CNC turning provides a foundation for building reliable products across various industries.

Comparing CNC Turning to Other Machining Methods

While CNC Turning Services are highly effective, they are often compared to other machining techniques like milling.

-

CNC lathe machining specializes in cylindrical parts, whereas milling is better suited for flat surfaces and complex 3D structures.

-

Turning delivers faster cycle times for shafts, rods, and bolts, while milling shines in tasks requiring slots, holes, and intricate surface details.

-

Both processes complement each other, but for round parts, turning remains the most efficient and precise solution.

High-Tolerance Manufacturing with CNC Turning

Many industries require parts that meet strict tolerance levels. CNC Turning Services are designed for high-tolerance manufacturing, ensuring components fit seamlessly into assemblies. The combination of advanced machinery and skilled programming enables consistent production even for the most demanding applications.

Importance of Surface Finish

The smooth surface finish produced by CNC lathe machining is another critical factor. Components with precise finishes not only look professional but also function more effectively in mechanical systems, reducing friction and wear over time.

Choosing the Right CNC Turning Partner

Selecting a reliable provider of CNC Turning Services is essential to ensure project success.

Experience and Expertise

A strong track record in delivering precision turned components is a key indicator of quality. Companies should look for partners with proven expertise in handling diverse materials and complex designs.

Advanced Equipment and Technology

Providers equipped with modern CNC lathes and the ability to deliver custom turning solutions are better positioned to meet varying client demands.

Quality Control Measures

Strict quality checks during cylindrical part manufacturing guarantee that parts meet exact specifications. This commitment to quality separates top-tier providers from average ones.

Competitive Pricing and Lead Times

Balancing affordability with efficiency is crucial. Choosing a partner who offers cost-effective metal turning services without compromising on speed or accuracy ensures maximum value for investment.

Future of CNC Turning Services

The future of CNC Turning Services is shaped by advancements in automation, AI-driven programming, and smart manufacturing. As industries demand faster production cycles and more complex parts, CNC technology will continue evolving to deliver superior results.

Integration with Industry 4.0

CNC systems are increasingly integrated into smart factories, enabling real-time monitoring, predictive maintenance, and seamless workflow management. This integration enhances productivity while reducing downtime.

Sustainability in CNC Machining

Modern metal turning services are also becoming more sustainable. By optimizing material usage and reducing waste, CNC turning supports eco-friendly manufacturing practices that align with global sustainability goals.

Conclusion

CNC Turning Services remain an indispensable part of modern manufacturing, offering unmatched precision, efficiency, and versatility. From CNC lathe machining to producing precision turned components, the process ensures high-quality results across industries. With the growing demand for cylindrical part manufacturing, custom turning solutions, and cost-effective metal turning services, CNC turning continues to prove its value.

For businesses seeking reliable, high-tolerance production, investing in professional CNC turning providers ensures lasting success and competitive advantage.